Description

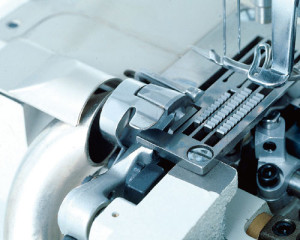

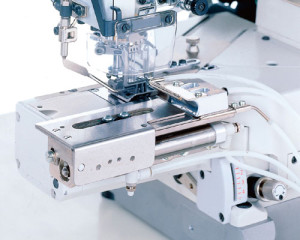

Electric hemming guide

For defect prevention – Fubric guide, Misalignment detection

- This guide automatically slides as soon as the sensor detects the cross seam section.

- This feature prevents misalignment due to stitch skipping or plyshifting on the cross seam sections, which tends to occur in blindstitch hemming operations.

- This device allows the operator to concentrate on the sewing operation.

Sewing machine models which the device can be installed on

GX5200 : Dry-head type, overedgers

![]()

![]()

![]()

| Subclasses | Use | Maximum speed | Fabric weight | Remarks |

|---|---|---|---|---|

| GX5204-02H/223 | Plain seaming/Blindstitch hemm | 7,000 sti/min | Light~Medium | |

| GX5203-12/223 | Blindstitch hemming | 7,000 sti/min | Light~Medium | |

| GX5205-12/223 | Blindstitch hemming | 7,000 sti/min | Light~Medium |

EX5200 : Overedgers

![]()

![]()

| Subclasses | Use | Maximum speed | Fabric weight | Remarks |

|---|---|---|---|---|

| EX5204-02H/223 | Plain seaming/Blindstitch hemm | 7,500 sti/min | Light~Medium | |

| EX5203-12/223 | Blindstitch hemming | 7,500 sti/min | Light~Medium |

EX5100 : Cylinder bed overedger

![]()

![]()

| Subclasses | Use | Maximum speed | Fabric weight | Remarks |

|---|---|---|---|---|

| EX5105-12/223N | Blindstitch hemming | 7,500 sti/min | Light~Medium | |

| EX5114-92M2/223N | Versatile | 7,500 sti/min | Light~Medium | 1-needle plain seaming, blindstitch hemming, 2-needle plain seaming |

EXT5100 : Vatiable top feed, cylinder bed overedgers

![]()

![]()

| Subclasses | Use | Maximum speed | Fabric weight | Remarks |

|---|---|---|---|---|

| EXT5105-12/223N | Blindstitch hemming | 6,700 sti/min | Light~Medium |